Automotive

Pneumatic Systems: Improving Industry Productivity using Omchele Solutions

Today’s industry requires effectiveness, dependability, and accuracy. It has become standard practice for businesses to automate foundational processes using pneumatic systems and is a standard practice across manufacturing, packaging, and assembling floors. Complexity and ease of operation are key factors for businesses to evaluate when sourcing components for pneumatic systems. Sourcing high-quality components for the components is just as important. Omchele is a supplier of such systems for industrial systems and automation pneumatic components designed to match the needs of the high-demand industrial scenarios. Explore their pneumatic solenoid valves here. Omchele provides a growing collection of items including pneumatic solenoid valves

Your curiosity deserves more—unlock deeper reads in Related Posts now!

What are Pneumatic Systems?

Mechanized pneumatic systems utilize compressed air as the primary medium for motion and energy transmission. Unlike hydropneumatic devices that depend on fluids, pneumatic devices depend on pressurized air to drive mechanisms such as actuators, cylinders, and valves. Because of their uncomplicated construction, high operating speeds, and a high level of safety, pneumatic systems are now a standard practice across industrial sectors.

In a complete pneumatic system, a number of constituent units can be assembled, such as a compressor, air tanks, air valves, mechanically driven actuators, pneumatic control units, and pneumatic air motors. Incorporating such systems into a production floor serves to automate lifting, positioning, and rotating operations, thus hypnotizing the need for human intervention. These systems in a B2B setting greatly automate and enhance the production, drastically reducing labor costs, and improving standardization.Omchele’s portfolio encompasses pneumatic solenoid valves and mechanisms which we stand behind for their proven functionality in a variety of industrial settings. Being the market leaders, we provide the most advanced pneumatic solenoid valves. The detailed portfolio of the pneumatic valves can be accessed here.

The Important Parts of a Pneumatic System

For B2B companies, redefining the operations and processes of the company would mean utilizing advanced technology. Understanding the parts of a pneumatic system is of utmost significance.

- Compressor. The system which creates the compressed air and feeds the system with air under certain predefined pressure and conditions.

- Air Treatment Units. Protect important parts and systems with clean, dry air by using a filter, lubricator, and regulators.

- Actuators. The mechanism which changes stored compressed air to mechanical movement in rotary actuators and cylinders.

- Valves. Devices which regulate the movement and pressure of the air including solenoid valves and valve systems.

- Control Systems. Electronic monitoring systems controlling the actuators including multiple sensors, software, and controllers.

Omchele valves maintain optimal functionality for operations and reliability to improve process and system performance. Manufacturing companies with fast loading times and controlled processes find multiple uses through these valves.

Advantages of Pneumatic Systems for B2B Companies

Pneumatic systems have distinct advantages for industrial processes which is why there is a wide adoption for them among B2B companies:

- Reliability: Much quieter and cooling much more efficient is pneumatic systems for which the cooling surface of the compressor is designed on a smaller area or uses much less water at very low pressures.

- Speed and Efficiency: Pneumatic systems have a quicker opportune responsive time due to high system pressures.

- Safety: The light weight of compressed air and the non-flammable property of pneumatic systems considerably diminishes the hazards associated with the high pressure hydraulic system or the elementary electrical hazards.

- Flexibility: These systems are more universal and applicable to a wider range of operations with smaller or larger scale processes.

- Cost-Effectiveness: The low system pressure, less water, and energy-efficient components and systems coupled with the very low maintenance costs suggest the great economic benefit.

These benefits can be achieved with minimal disruption to production and other processes through the use of Omchele pneumatic components. Using high quality pneumatic systems will lead to increased productivity and product quality.

Applications of Pneumatic Systems in Industry

Pneumatic systems are diverse in use case and can be incorporated in many varied industrial processes:

- Manufacturing: Used in the automation of rotary and linear pneumatic actuators in assembly lines, material handling systems, and other presses.

- Packaging: Used in high precision filling machines for labeling and other sorting equipment to automate sorting.

- Automotive Industry: Used in control of robotic arms, lifting and other assembling automation.

- Food and Beverage: Used in safe processing machines to avoid any risk of contamination.

- Pharmaceuticals: Supports the sterile processing and careful handling of delicate products.

Omchele understands the applications and all of the associated requirements and has designed pneumatic solutions to satisfy those rigorous demands. For B2B companies, the integration of these systems assures operational efficiency, conforms to industrial requirements, and is designed for future scalability. Read more on their products here.

Making a Choice on what Components to use

The system performance depends on the chosen system components. B2B companies should take into account:

- Operating Pressure: Each of the components must be able to manage the defined and expected pressure levels for a range of applications.

- Flow Requirements: For actuators to function at their desired output and not diminish in performance efficiency, a steady and sufficient flow rate is needed.

- Environmental Conditions: Components must be resistant to a range of and extreme temperatures, increased levels of humidity, and dust and spray from chemicals.

- Compatibility: Assure that valves, actuators and all other components in the control system interfaces.

- Automation Needs: For contemporary industrial layouts, precise control in the system is available through automated solenoid valves and other controllers.

Working with businesses to select suitable system components which are guaranteed to function of the system with a maximum uptime, Omchele offers assistance and a pneumatic system designed to ensure minimum operational danger.

Companies looking to invest in Step. Products designed to meet the most taxing Industrial automation problems with reasonable pricing will not be disappointed by Omchele.

Conclusion

Modern industry relies on pneumatic systems for the speed, efficiency, and reliability critical to B2B operations. Businesses can enhance production, lower maintenance expenses, and improve the safety of operations with the help of Omchele pneumatic components, like solenoid valves.

Productivity, efficiency, and enduring industrial achievement can be gained from the correct omnipresent pneumatic system like those offered by Omchele. Omchele helps B2B firms thrive in a fiercely competitive industry with precision and dependable systems built to rigid industrial standards. Explore the collection of pneumatic solenoid valves https://www.omchele.com/es/pneumatic-valves/pneumatic-solenoid-valves/.

You’ve only seen the surface—Explore More to uncover unseen stories!

Automotive

How Precision Manufacturers Can Overcome Thread Tapping Challenges to Boost Efficiency and Cut Costs by 40%

Introduction

In the precision manufacturing industry, thread tapping is known to be one of the bottlenecks experienced in the production lines. This is because manufacturers are normally associated with problems of premature tap wear, lack of quality threads, and, at times, tap breakages, among others Thread Tapping Solutions. This is due to the fact that there is no scientific approach to link the type of tap to be used and the material it is dealing with, among others.

This piece offers a comprehensive, data-informed approach to choosing taps, or threads, to help readers form effective approaches to improve consistency, durability, and, most importantly, reduce costs. To better understand how materials, tap geometrics, and tap parameters work in tandem, manufacturers can turn their threading process around by considering the aspects that are explored below.

What Constitutes a Scientific Approach to Thread Tap Selection?

Scientific method of taper selection in taps goes beyond the trial-and-error process because scientific selection optimizes the decision-making process by considering a number of factors such as the material of the workpiece, the type of thread, and the machining conditions.

1. Difference between Scientific & Empirical Methods

Empirical approaches work by relying on past experiences, often in the form of guidelines. Such methods tend not to work in complex situations. In scientific thread tap selection, there is reliance on scientific principles and real-time information, often in relation to matters such as the hardness of the material and geometry of the holes.

2. Key Variables in Systematic Tap Selection

These key variables are raw material type (for instance, aluminum or stainless steel), thread type (blind or through hole), and machining variables such as rigidity and cooling rates. By evaluating all such variables, one can easily eliminate mistakes such as clogging due to chips or tool breakage. Adding databases or software for thread taps also makes this process easier.

3. Implementing Data-Driven Decision Making

To incorporate data-informed decisions, one needs to focus on the historical data of performance, feasibility studies, and predictions. For example, tracking the tap lifecycle and failure rates can assist in improving the criteria of selection. A proactive approach ensures that there is continuous improvement and it is according to quality requirements, such as ISO 9001.

How Does Material Composition Dictate the Optimal Tap Geometry?

Properties of materials can directly affect tap geometry, since various materials need to be handled in different ways regarding cutting force, heat, and chip removal. This knowledge is critical in determining which type of tap to use in production.

1. Tap Geometry for Different Material Families

For aluminum, being soft and sticky, the best kind of tap for use is the high helix angle spiral flute tap. In the case of hard materials, such as stainless steel, the best type of tap for use is the spiral point tap. Quotations included from reliable sources like the ASM Handbook Volume 01: Properties and Selection: Irons, Steels, and high performance alloys add to the validity of the suggestions.

2. The Role of Helix Angle and Flute Design

The value of the helix angle and the flute type influence the chip management in tapping. A higher value of the helix angle is beneficial for non-ferrous materials, which removes chips from blind holes, whereas a smaller value is better for brittle materials, including cast iron. Because these factors promote chip packing, they directly affect efficiency in the thread tap.

3. Case Examples Based on Material Groups

For instance, in machining the high-temperature alloy, one requires a tap with a coating of TiCN and positive rake angle to resist wear. Again, in machining plastic material, one requires a polish surface tap to prevent material binding to the surface. These scenarios depict how each type of material requires taps with unique geometry to prevent defects.

What Are the Key Parameters for Maximizing Thread Tap Efficiency and Tool Life?

The process parameters of cutting speed, feed rate, and coolant delivery need to be optimized and are critical for obtaining the maximum possible performance of the tap.

- Optimizing Tapping Speed and Feed Rates: Optimizing tap speed and feed rate is essentially optimizing the aggressiveness and accuracy. Higher tap speed means lower cycle time and increased heat generation, whereas unconservative feed can result in poor chip removal. Based on the work material recommendations, improving efficiencies of up to 30% can be achieved without compromising the quality.

- The Impact of Coolant and Lubrication: The type of coolant used and the coolant pressure is an important factor in cooling and chip evacuation. For example, high pressurecooling systems increase the efficiency in deep-hole tapping by reducing friction. The type of coolant used will increase tool life, hence reducing the cost of thread tapping.

- Parameters Monitoring and Adjustment Within Real-Time: By using sensors for torque and vibration monitoring, there is real-time parameter adjustment. This helps to avoid the breakage of taps and helps in maintaining consistency. Its implementation in the form of a scientific approach brings improvement in efficiency and cost-cutting.

How Can Manufacturers Meet Consistent Accuracy in Mass Production of Tapping?

Precision in mass production calls for process control and quality assurance. This is important for achieving consistency, which contributes to meeting industry standards.

1. Implementation of Statistical Process Control (SPC)

SPC methods analyze production data for early signs of deviations. Based on thread depth and diameter, for example, it becomes possible to control the accuracy of thread tapping for large series products. This fits well into the standards mentioned in ISO 9001, which emphasizes process validation.

2. Tool Life Management and Predictive Maintenance

proactive management of tool lives includes replacing the taps based on past data. For instance, the use of torque limits in the change of taps prevents macro-defects in the taps. Such an approach ensures that the taps function effectively in the CNC tapping operations.

3. Quality Assurance through Certification

Companies that comply with certifications such as ISO 9001 and IATF 16949 have developed procedures for the management of the tools. These provide traceability and the assurance that every thread conforms to specifications, which again builds confidence in the accuracy of the thread tapping solutions.

What Framework Enables a True Cost-Effective Thread Tapping Strategy?

Switching the focus from initial tap cost to total cost per hole is essential for achieving long-term savings. The complete framework analyzes all the different cost components comprised of tool procurement, downtime, and scrap.

- Analyzing Total Cost per Hole: Cost-effective thread tapping considers a number of factors, including tool life, machining time, and rejection rates. For example, a premium tap may have a longer life, although more expensive initially, thus it is cheaper overall. A detailed model for thread tapping cost analysis gives justification for such decisions.

- Case Study: Optimization for Cost Reduction: Automotive Parts Case: Optimizing tap selection and parameters reduced the cost by 40% due to reduced tool changes and scrap. This shows that the scientific approach yields tangible benefits. For further insight, read the following about resources on CNC milling services which discuss cost models.

- Cost-benefit analysis in planning: Cost-benefit analysis in production planning ensures that decisions are well-considered. With the help of lifecycle cost calculators, among other tools, options can be reviewed to strategically alter course to cost-effective thread tapping without compromising quality.

How to Evaluate a Supplier’s Capability in Delivering Reliable Thread Machining Solutions?

Supplier selection includes an assessment of technical capabilities, certification, and reputation. A proper evaluation then gives assurance that the partner is well capable of providing good services.

1. Technical Capabilities Assessment and Databases

A reliable supplier should come with comprehensive material databases and case studies. For example, verifying their experience with projects such as engine block threading indicates capability. This checks the box for the criteria in finding a reliable CNC tapping services partner.

2. The Importance of Industry Certifications

AS9100D and other certifications dealing with aerospace signals that the companies manufacturing these parts work to very high standards. Thus, those suppliers have a right to say that they are committed to quality and will be able to make better preparation for such a large volume of CNC tapping services.

3. Rating of Engineering Support and Responsiveness

Strong engineering support teams offer customized solutions and fast response. Assessing their DFM analysis offering and customer reviews provides an idea of reliability and assurances of fit for a precision-driven project.

Conclusion

Thread tap selection is well served by a scientific, systematic approach to overcome efficiency and cost challenges. With data-driven methods, quality consistency is possible along with minimization of waste and enhancement of profitability. Threading, a bottleneck, is transformed into a competitive advantage with this strategy.

FAQs

Q1: What is the first step in selecting the right thread tap?

A: Proper workpiece material and hole specification analysis is the first step. Depending on material hardness and machinability, tap material and geometry are prescribed in order to avoid any chip-packing problem that can easily arise.

Q2: How can I know if a tap will be needed to be replaced prior to producing scrap parts?

A: Look for symptoms, such as increased tapping torque, or deterioration in surface finish. Data-based proactive management in tool life avoids quality issues in mass production.

Q3: What are the main differences between the hand taps and machine taps for the CNC applications?

A: Yes. The tolerances and geometries are tighter to run at high speeds. Using hand taps in the CNC machines results in poor quality and rapid failure.

Q4: What are the benefits offered by the use of spiral-pointed taps over the use of the spiral-fluted ?

A: Spiral point taps remove chips by pushing them through for through holes, while removing chips from blind holes requires pulling them with a spiral fluted tap. This is dependent on the type of hole being drilled to avoid accumulation of chips.

Q5: What is the effect of coating on a tap?

A: Coated materials such as TiN have low friction and long lifetimes. The use of coatings optimized for certain materials leads to improved performance.

Author Bio

The author is a precision manufacturing specialist with LS Manufacturing, a company which assists engineers in overcoming difficult part challenges in sectors such as aviation and autos. ISO 9001 and AS9100D certified, they provide quality services to their clients using their technological expertise. To receive a data-driven thread machining quote and DFM analysis, click here through their online custom CNC milling services.

Automotive

The Hidden Costs of Ignoring Diesel Fuel Injection Problems

Want to dodge a repair bill that’ll wreck your budget?

Diesel fuel injection pump failure is among the worst expenses for Diesel Fuel Injection Problems any diesel owner can endure. What’s worse is most diesel owners never see it coming.

Thing is…

There are warning signs way before your pump completely fails. Unfortunately, most people ignore them until it’s too late and by then, the real repair costs start to add up.

The good news? There are ways to spot fuel injection problems before they get too far out of hand.

What you’ll discover:

- How much it REALLY costs to have your fuel injection pump fail

- Warning signs you should NEVER ignore

- How one broken pump destroys your entire fuel system

- Tips to prevent expensive diesel fuel pump repairs

How Much Does Diesel Fuel Injection Pump Failure Cost?

Most diesel owners mistakenly believe their fuel injection pump is one piece that needs replacing. If your diesel fuel pump goes bad, the repercussions are MUCH worse.

Once your injection pump goes bad, you’re looking at metal particles contaminating your entire fuel system. That includes injectors, fuel lines, fuel rail and EVEN your fuel tank.

How much does that cost you?

Between parts and labor, pump repair bills caused by contaminated CP4 injector pumps can range from $10,000 to $18,000. Yup, you read that correctly. One broken fuel injection pump could cost you that much to replace your injectors, high-pressure fuel lines, return lines + a full system flush.

And those are just repairs to your diesel truck. Did you account for lost income from not being able to work while your truck is in the shop? Diesel engines average between 2.5 to 4.5 more days of downtime per year than gasoline engines.

GoldFarb Inc does a great job at breaking down the most common diesel pump issues. Every diesel engine owner should read that breakdown before fuel injection failure ruins your engine.

Wow….$10,000 to $18,000. Serious jaw dropping moment there.

Warning Signs You Should NEVER Ignore

Patience is the biggest mistake most diesel owners make. One of the many things people don’t realize is diesel fuel injection pump failure doesn’t happen overnight.

These pumps provide plenty of warning signs before things go from bad to worse. Here are some things to look out for if you think your fuel injection or Diesel Fuel Injection Problems may be going bad.

Check for these common symptoms:

- Hard starting or complete failure to start: Fuel pump can’t build up enough pressure to turn the engine over.

- Rough idling and engine misfires: Irregularities in fuel delivery cause the engine to jerk and misfire.

- Loss of power when accelerating or pulling a load: Pump can’t keep up with demand.

- Excessive exhaust smoke: Fuel isn’t being delivered properly, causing white smoke or black smoke.

- Strange noises coming from the engine: Whining or knocking sounds near the fuel pump area are bad news.

Any combination of these signs means something is wrong with your fuel injection pump. The longer you let it go, the worse the problem becomes.

A needed rebuild can easily turn into a full fuel system replacement. And that alone bumps the repair estimate from pricey to devastatingly expensive.

How ONE Broken Pump Destroys Your Entire Fuel System

Here’s why you should NEVER ignore those hidden costs mentioned above.

Your diesel fuel injection pump is built to handle high amounts of pressure. Common rail systems nowadays generate upwards of 29,000 PSI. When the parts inside your pump start to wear out, they flake metal shavings into the fuel sent through those lines.

Metal Shavings = THE devil.

See, those shavings don’t just stay in your pump. They spread like wildfire through your entire fuel system. The high-pressure fuel lines distribute contaminated fuel to each injector. Return lines cycle the debris right back through the fuel pump.

Fast forward several miles down the road.

You’ve got a fuel system that’s littered with metal debris. What started as just a problem with your pump turns into needing to replace your fuel injectors, lines, filters + fuel rail.

This exact problem was why Bosch’s CP4 injection pump wreaked havoc on millions of diesel trucks around the world. Running on low-sulfur diesel fuel made the pump’s internal design highly susceptible to failure. Automotive Fleet recently reported that maintenance and repair costs increased by 4.9% in early 2025. Fuel injection pump failure was one of the biggest contributors to this uptick.

Essentially, the debris was so bad that system flushing was never an option. Fuel pumps, injectors, lines and filter housing all need replacing.

See how expensive ONE fuel pump problem can become?

Tips to Prevent Costly Diesel Pump Failures

Now you know what can happen when you neglect those hidden fuel injection pump problems. The best way to combat fuel injection failure is by preventing them from happening in the first place. It’s much easier (and cheaper) to follow this maintenance advice than sinking thousands of dollars in repair bills.

Help prevent fuel injection failure by doing the following:

- Change your fuel filters regularly. A dirty fuel filter forces your fuel pump to work harder which accelerates wear and tear. Changing your fuel filter is cheap insurance compared to what could go wrong if you don’t.

- Only use high quality diesel fuel. Low-grade diesel with poor lubricity ranks highly as a cause of premature pump failure. Fuel additives help, but try to use the cleanest fuel you can find.

- Keep an eye out for water contamination. Water builds up in your fuel system and causes severe corrosion to fuel system components.

- Don’t ignore your check engine light. Diesel engines are complex machines with tons of computer monitoring. If your check engine light comes on with a fuel pressure fault code, pull over and diagnose the issue as soon as possible.

- Get regular inspections. Having your fuel system inspected by a certified diesel tech is WAY cheaper than fixing a total loss.

Truth bomb:

Fuel filters are cheap. As long as your truck runs, bi-yearly maintenance appointments take maybe 4 hours of your time. Rebuilding an entire fuel system takes weeks and costs over $10,000.

The moral of the story? Spend a little now and save yourself a lot in the future.

Wrap Up

Diesel fuel injection problems are NEVER something to take lightly. Ignoring the hidden costs will come back to haunt you when you least expect it.

Just remember:

- Repair bills can range from $10,000 to $18,000 when the entire fuel system needs replacement due to pump failure.

- Pay attention to warning signs like hard starting Diesel Fuel Injection Problems, rough idle and loss of power. They don’t go away on their own.

- Metal contamination from a failing fuel injection pump will destroy your injectors, fuel lines and filters.

- Prevention is always cheaper than paying for major repairs.

Don’t wait until your truck refuses to start. Watch for signs of fuel injection problems and do your best to prevent them. You’ll thank yourself later!

Step beyond the basics—explore expert-level tips here at Awareness Ideas.

Automotive

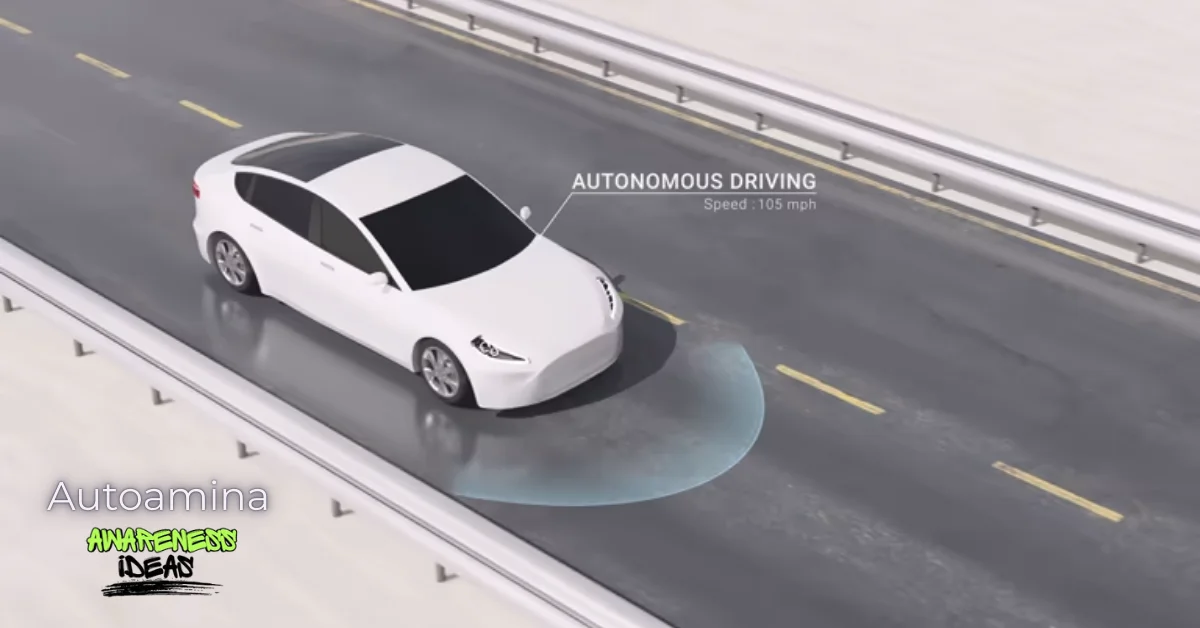

Autoamina: The Rise of Intelligent Autonomous Vehicles

Welcome to the world of Autoamina, where intelligent autonomous vehicles are not just a futuristic dream but a present-day reality. As technology advances at lightning speed, we find ourselves on the brink of a transportation revolution. Traditional vehicles are transforming into smart machines capable of navigating our roads with minimal human intervention. This shift is not only about convenience; it’s about safety, efficiency, and redefining mobility as we know it.

Join us as we explore the evolution that has brought us here, what makes these autonomous vehicles tick, their advantages and potential pitfalls, and how they will reshape the automotive landscape for years to come. Get ready for a thrilling journey ahead.

The Evolution of Vehicles

The journey of vehicles began centuries ago. Horse-drawn carriages were the norm, offering a glimpse into transportation’s potential.

Then came the steam engine in the 19th century, revolutionizing travel and trade. This marked a significant leap forward, paving the way for motorized vehicles.

The early 20th century introduced gasoline-powered cars that changed everyday life forever. Henry Ford’s assembly line made automobiles accessible to the masses, leading to an explosion of personal mobility.

Fast forward to recent decades; innovations like electric powertrains and hybrid models emerged as responses to environmental concerns. Technology continued evolving with computers becoming integral parts of vehicle design.

Today, we stand at a pivotal moment with autonomous technology on the horizon. Vehicles are no longer just machines; they are evolving into intelligent systems capable of navigating complex environments without human input.

What are Autonomous Vehicles?

Autonomous vehicles, often referred to as self-driving cars, are a game-changer in transportation. They rely on a blend of artificial intelligence, sensors, and advanced algorithms to navigate roads without human intervention.

These vehicles come equipped with technologies like LIDAR, radar, and cameras. Together, they create a detailed map of surroundings. This allows them to identify obstacles, read traffic signals, and make real-time decisions.

Levels of autonomy vary significantly among these vehicles. Some offer basic assistance features like lane-keeping or adaptive cruise control. Others operate fully autonomously under certain conditions.

The allure lies in their potential to enhance road safety and reduce accidents caused by human error. As technology progresses, the dream of widespread adoption seems closer than ever before. The future is not just about getting from point A to B; it’s about how we redefine mobility itself.

Advantages of Autonomous Vehicles

Autonomous vehicles offer a range of advantages that can transform transportation. One major benefit is enhanced safety. With advanced sensors and algorithms, these vehicles can significantly reduce the risk of accidents caused by human error.

Another advantage is increased efficiency on the roads. Autonomous systems optimize driving patterns, resulting in smoother traffic flow and reduced congestion. This efficiency also leads to lower fuel consumption, making them more environmentally friendly.

Convenience is another compelling factor. Passengers can use travel time for work or relaxation rather than focusing on driving. This shift could change how we view commuting altogether.

Accessibility improves as well; autonomous vehicles can provide mobility solutions for those unable to drive due to age or disability. The potential impact stretches beyond just personal convenience it’s about creating a smarter society with greater connectivity and inclusivity in transportation options.

Challenges and Safety Concerns

As autoamina technologies advance, challenges and safety concerns arise. One major issue is the reliance on complex algorithms. These systems must interpret vast amounts of data in real time. Even a minor glitch could lead to serious consequences on the road.

Cybersecurity poses another risk for autonomous vehicles. Hackers might exploit vulnerabilities, potentially gaining control over a vehicle’s functions. This threat raises questions about privacy and data protection.

Human interaction adds more complexity to the equation. Autonomous vehicles need to navigate unpredictable behaviors from pedestrians and other drivers. Miscommunication can result in accidents or misunderstandings.

Regulatory hurdles also complicate matters. Different regions may have varying laws regarding autonomous driving technology, which affects deployment strategies globally. Establishing standardized guidelines is essential for widespread acceptance of these innovations in transportation.

Future of Autonomous Vehicles

The future of autonomous vehicles is poised to reshape how we perceive transportation. With advancements in artificial intelligence and machine learning, self-driving cars will soon boast capabilities that many can only dream of today.

Imagine a world where traffic jams are minimized. Vehicles communicate with each other, optimizing routes for efficiency. This interconnectedness could drastically reduce commute times.

Public acceptance will play a pivotal role in this evolution. As more people experience the convenience and safety of intelligent vehicles, the stigma around automation may fade away.

Urban planning will also undergo significant changes as cities adapt to accommodate self-driving technology. Parking spaces might transform into green areas or community hubs since cars won’t require traditional parking anymore.

Manufacturers are racing against time to integrate cutting-edge technology while ensuring safety standards remain uncompromised. Innovations like enhanced sensor systems and real-time data processing are key components driving this future vision forward.

Impact on the Automotive Industry

The emergence of Autoamina is reshaping the modern automotive industry. Traditional manufacturing processes are being challenged as tech companies and startups enter the scene.

Automakers must adapt to a new reality where software and data management play crucial roles. This shift demands collaboration between engineers, designers, and software developers.

Moreover, supply chains are evolving. Components like sensors, cameras, and AI systems have become vital parts of vehicle production. The need for skilled workers in these areas is on the rise.

Consumer expectations are changing too. People are looking for more than just transportation; they want connected experiences that enhance their daily lives.

As autonomous vehicles gain traction, businesses across sectors will feel the ripple effects. Ride-sharing services may expand rapidly while traditional ownership models could decline significantly.

Conclusion

The world of autoamina is rapidly transforming our understanding of transportation. From early steam-powered engines to today’s sleek electric models, the evolution of vehicles reflects humanity’s relentless pursuit for better mobility.

Autonomous vehicles represent a significant leap in this journey. These intelligent machines utilize advanced sensors and software algorithms to navigate their surroundings without human intervention. Such innovations are not just impressive technological feats; they promise to reshape how we think about travel.

The advantages are compelling enhanced safety, reduced traffic congestion, and increased accessibility for those unable to drive themselves are just a few benefits that autonomous vehicles offer. Imagine a future where accidents decrease significantly because computers can react faster than humans or where elderly individuals gain independence through self-driving technology.

However, challenges remain on the road ahead. Safety concerns linger as we entrust machines with lives at stake. Regulatory hurdles must be addressed, and public trust needs fostering before fully autonomous cars become commonplace.

Looking forward, the landscape for these vehicles continues evolving at breakneck speed. Innovations in artificial intelligence will enhance decision-making processes while improving connectivity between cars and infrastructure will create smarter cities.

As manufacturers adapt to this new paradigm shift brought by autoamina, traditional automotive players must rethink their strategies or risk obsolescence amidst startups vying for market share in smart mobility solutions.

This transformation is not simply about technology; it represents a cultural shift towards embracing change in how we commute daily. With every breakthrough comes an opportunity one that could redefine our relationship with transportation entirely down the line.

-

General6 months ago

General6 months agoFelixing: A Philosophy of Turning Simple Ideas into Wonders

-

Health5 months ago

Health5 months agoLufanest: Effective Local Anesthesia with Fewer Risks

-

General6 months ago

General6 months agobardoek: The Artistic Heritage Inspiring Modern Creative Trends

-

Entertainment5 months ago

Entertainment5 months agoهنتاوي.com: Your Gateway to Arabic Anime Content

-

General5 months ago

General5 months agoDiscover Anonib AZN: An Anonymous Asian Forum

-

Fashion7 months ago

Fashion7 months agofashionisk .com – Your Ultimate Guide to Trendy, Smart Fashion

-

Lifestyle7 months ago

Lifestyle7 months agoMariano Iduba: A Visionary Leader in Global Digital Growth

-

Fashion7 months ago

Fashion7 months agoCasîo: Explore Legacy, G-SHOCK Watches, Keyboards, and More